Protective coating of your

pistons

pistons

UP TO 1000% IMPROVED WEAR RESISTANCE

Withstands up to 2000 °C

Friction coefficient ≤0.010

Increase in torque and capacity up to 5%. The turbocharging response improves, and the temperature of the engine coolant and motor oil decreases.

Thermoregulation

No friction

Capacity

Reliable barrier against friction and temperature

Extreme temperatures and high friction are factors that disable any internal combustion engine.

We have developed a new formula for metal-ceramic coatings obtained by a special method of micro-arc oxidation

We have developed a new formula for metal-ceramic coatings obtained by a special method of micro-arc oxidation

Innovative technology of the USSR space program, modified by our scientists

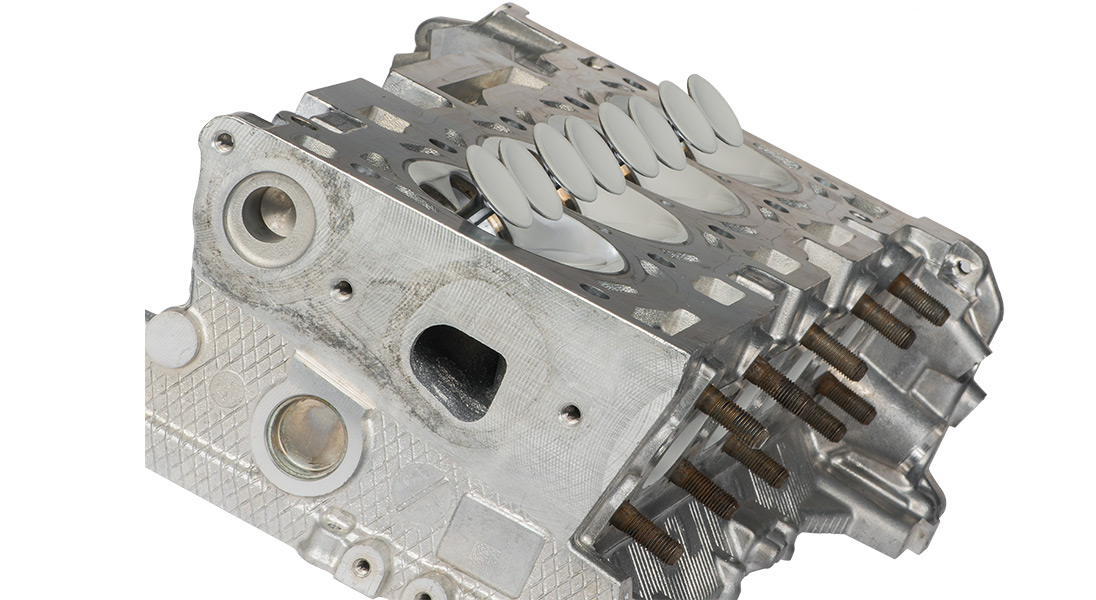

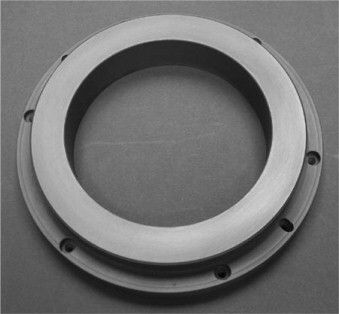

We have developed a special corundum (the second strongest mineral after diamond) AL2TEO coating for aluminum pistons.

How does it work?

COATING TESTING

Strenght test

Fire test

Strenght test

Our patented method has a number of advantages over the technologies offered on the market:

- Maximum density at comparative cost

- Coating thickness up to 500 microns

- The possibility of covering small holes with a diameter of 4 mm

You can pack and send your spare parts to our warehouse in any convenient way:

[We accept shipping at the expense of the sender]

- Russia, Novosibirsk, Nikolaeva str. 11, 406

[We accept shipping at the expense of the sender]

We will not accept a parts:

You can assess the condition of the spare part by sending us a photo.

- beaten

- crumpled

- with deep scratches and chips

- dirty

You can assess the condition of the spare part by sending us a photo.

The parts can be covered:

- The surface of the intake and exhaust valves

- Exhaust ports

- Piston-cylinder pair

Dispatch

Conditions

Coating

Your pistons - are our coating

The production has two automated coating lines, a manual service line for small details and a processing area for large-sized products.

10 - 500 μm

≤0.010

Coefficient of friction

up to 7000 V

Breakdown voltage

10 W/(m∙K)

Heat transfer coefficient

Coating thickness

up to 3500 Hv

Coating microhardness

up to 2000 °C

Thermal resistance

AL2TEO surface characteristics

- reduction of fuel consumption up to 10%,

- wear reduction,

- increasing the power and resource of the internal combustion engine,

- the possibility to remove the air filter,

- an increase in efficiency by 5-7% due to an increase in the adiabaticity of the combustion chamber.

Result

The coating of pistons and other elements of the crank mechanism ensures reliable operation of the engine for a long time, increases the power and resource of modern engines.

Our coverage advantages

Wide range of applications

Expanding the range of application of aluminum, titanium, and magnesium parts through the use of MAO-coating

Expanding the range of application of aluminum, titanium, and magnesium parts through the use of MAO-coating

Increased protective and decorative properties

Protective and decorative properties are higher than those of galvanic or any other coatings

Protective and decorative properties are higher than those of galvanic or any other coatings

1

2

3

4

Machining parts with complex geometry

Machining of parts with complex geometry, blind and through holes, threads

Machining of parts with complex geometry, blind and through holes, threads

Machining of any Al, Ti, Mg alloys

We can process any aluminum, titanium, magnesium alloys

We can process any aluminum, titanium, magnesium alloys

Our patented method has a number of advantages over technologies available on the market:

Comparison of AL2TEO technology with MAO of other companies

- Hanging density at comparative cost

- Consistent coating quality during serial production

- Low energy consumption per unit of coating surface

- Coating thickness up to 500 μm

- AL2TEO makes it possible to obtain coatings with controlled characteristics and homogeneous hardness

- Ability to cover small holes

- Thermal resistance up to 2000 °C

- Breakdown voltage up to 7000 V

Apply for corundum coating

Contact

+971 52 102 0256

support@al2teo.com

Silicon Oasis,

support@al2teo.com

Office

DubaiSilicon Oasis,

the SIT Tower, office 1810

Apply for corundum coating