We offer unique coatings obtained by micro-arc oxidation for aluminum, titanium and magnesium products

We offer unique coatings obtained by micro-arc oxidation for aluminum, titanium and magnesium products

Application

Our coverage advantages

Wide range of applications

Expanding the range of application of aluminum, titanium, and magnesium parts through the use of MAO-coating

Machining of any Al, Ti, Mg alloys

We can process any aluminum, titanium, magnesium alloys

Expanding the range of application of aluminum, titanium, and magnesium parts through the use of MAO-coating

Machining of any Al, Ti, Mg alloys

We can process any aluminum, titanium, magnesium alloys

Increased protective and decorative properties

Protective and decorative properties are higher than those of galvanic or any other coatings

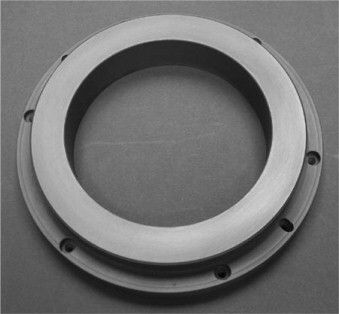

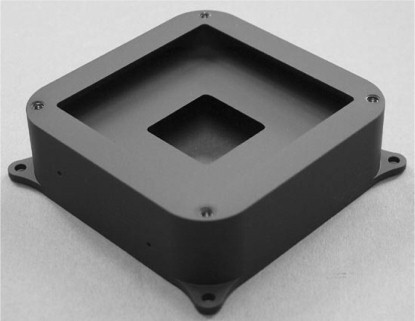

Machining parts with complex geometry

Machining of parts with complex geometry, blind and through holes, threads

Protective and decorative properties are higher than those of galvanic or any other coatings

Machining parts with complex geometry

Machining of parts with complex geometry, blind and through holes, threads

10 - 500 μm

≤0.010

Coefficient of friction

up to 7000 V

Breakdown voltage

10 W/(m∙K)

Heat transfer coefficient

Coating thickness

up to 3500 Hv

Coating microhardness

up to 2000 °C

Thermal resistance

What steps does the coating procedure consist of?

1

Application

You leave a request for a cost estimate

2

Costing

The same day we make the calculation and send you a sample contract for your signature

3

Detail covering

We design and create the detail, then make the coating

4

Job acceptance

You accept and pay for each step of the work

Send an enquiry

Services

Al, Mg and Ti details coating

Details covering from 1 pc.

1-7 days

1-7 days

3D model creation

Detail manufacturing

Detail manufacturing

Design department

MAO-application equipment supply

Manufacturing, delivery and start-up of machinery

2-3 month

2-3 month

Extra services

MAO-using devices and mechamisms development